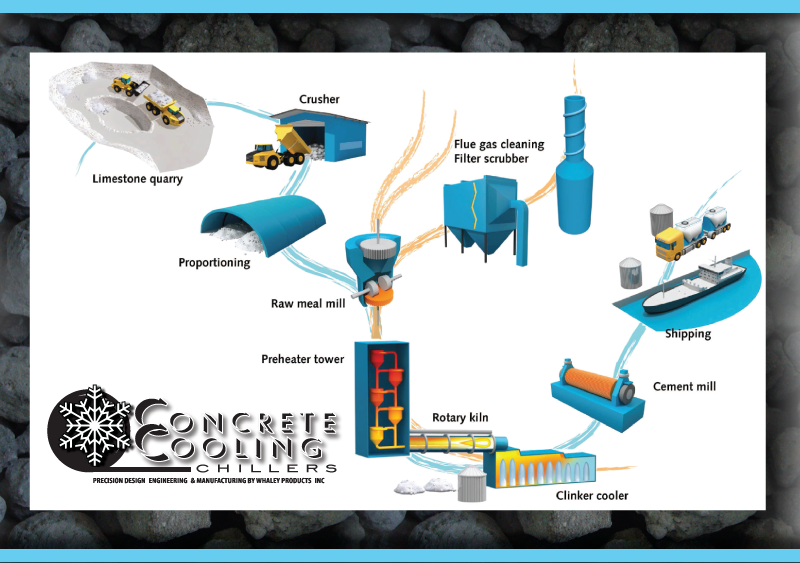

Creating clinker is the first step in the manufacturing process of cement. This occurs inside of the cement kiln. Limestone and clay are crushed and mixed together. They are then fed into a rotating kiln that is heated by an internal flame reaching 2000⁰C. The kiln is set at a slight incline so that when the slurry reaches a molten state it slides forward and begins cooling. The slurry refers to the four basic oxides present in the limestone and clay. They must be present in the correct proportions of 65% calcium oxide, 20% silicon oxide, 10% alumina oxide, and 5% iron oxide. When these oxides are heated at high temperatures, they form new compounds called silicates, aluminates, and ferrites of calcium. The newly formed compounds create marble sized granules known as clinker. This is the material that causes the hardening of cement when it comes in contact with water. This clinker is then ground into powder for packaging and is then ready for use in concrete mixes.